The Benefits of Rapid Prototyping in China: A Comprehensive Guide

In today's fast-paced business environment, companies are constantly seeking ways to improve product development, reduce time-to-market, and enhance design precision. One of the most effective strategies to achieve these goals is through rapid prototyping, especially in the vibrant manufacturing landscape of China. In this comprehensive guide, we will explore what rapid prototyping is, its numerous benefits, and how DeepMould.net, a leader in metal fabrication, can help your business harness these advantages to drive success.

What is Rapid Prototyping?

Rapid prototyping refers to a set of techniques used to quickly fabricate a scale model or a working prototype of a physical part or assembly. This process is crucial in the product development cycle as it allows designers and engineers to:

- Visualize concepts and ideas

- Identify and rectify design flaws

- Gather user feedback

- Test functionality

- Accelerate the overall production timeline

In essence, rapid prototyping enables businesses to iterate quickly and effectively, ensuring that the final product meets the desired specifications and market needs.

Why Choose China for Rapid Prototyping?

China has become a dominant player in the global manufacturing arena, particularly for rapid prototyping services. Here’s why:

1. Cost Efficiency

One of the most appealing aspects of conducting rapid prototyping in China is the significant cost savings. The lower labor costs and material prices allow for high-quality prototypes to be produced at a fraction of the cost found in other manufacturing hubs around the world. This cost advantage allows companies, especially startups and small businesses, to allocate their budgets more effectively while still achieving high-quality outcomes.

2. Speed of Production

Time is of the essence in product development. With the vast number of advanced manufacturing facilities in China, companies can achieve rapid turnaround times for their prototypes. Using cutting-edge technologies such as 3D printing, CNC machining, and injection molding, prototyping can be completed in days rather than weeks. This speed enables businesses to quickly move from ideation to market testing.

3. Advanced Technology and Expertise

China’s manufacturing industry is renowned for its adoption of advanced technologies. Many firms incorporate the latest in CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software, coupled with high-precision machinery, to deliver exceptional results. This level of expertise ensures that the prototypes produced are not only aesthetically pleasing but also functionally sound.

4. Accessibility to Materials

China's well-established supply chains provide easy access to a wide range of materials needed for prototyping. From metals and plastics to composites, manufacturers can source materials quickly and efficiently, reducing delays in the prototyping process. This accessibility significantly enhances the flexibility and options available in the prototyping phase.

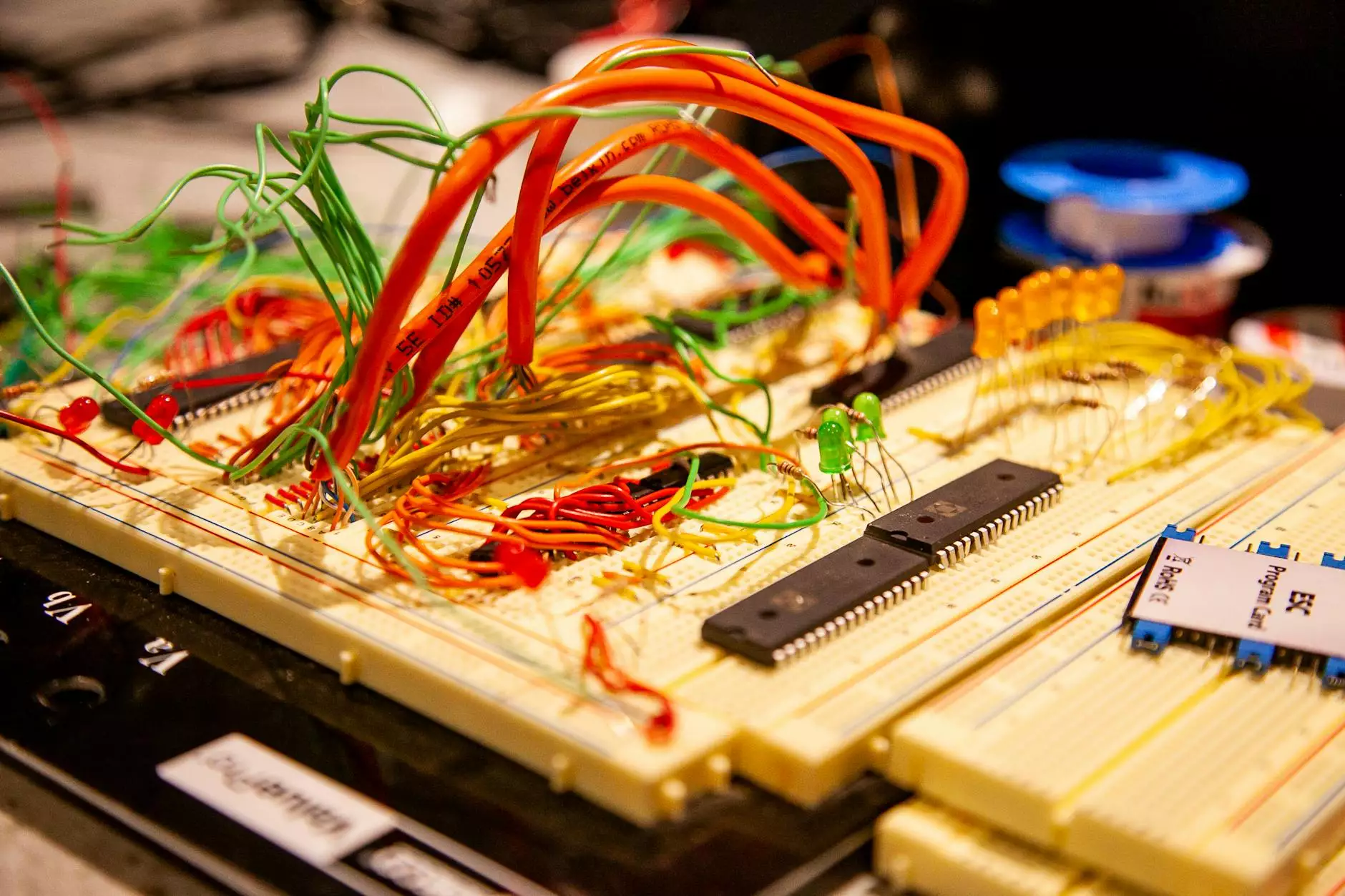

The Processes Involved in Rapid Prototyping

Understanding the various manufacturing processes involved in rapid prototyping can help businesses choose the appropriate method for their needs. Here are some of the most common techniques:

1. 3D Printing (Additive Manufacturing)

3D printing is arguably the most recognized method of rapid prototyping today. This process builds prototypes layer by layer from digital models, using materials like plastic, resin, or metal powders. The advantages include:

- Complex geometries that would be impossible to achieve with traditional methods

- Minimal waste of materials

- Fast iteration cycles

2. CNC Machining

CNC machining (Computer Numerical Control) involves removing material from a solid block to create the desired shape. This method provides:

- High precision and accuracy

- Ability to work with a wide range of materials

- Durable prototypes suitable for functional testing

3. Injection Molding

While traditionally used for mass production, injection molding can also be configured for rapid prototyping. It involves creating a mold and then injecting material, such as plastic, into it. Key benefits include:

- High-quality surface finish

- Scalability for small batch productions

Benefits of Rapid Prototyping in Your Business Strategy

The advantages of incorporating rapid prototyping into your business strategy are manifold:

1. Enhanced Design Quality

With the ability to test and iterate designs rapidly, your team can refine products based on real-world feedback. This iterative process leads to improved design quality and higher customer satisfaction.

2. Reduced Risk

By identifying potential flaws and issues early in the development process, businesses can mitigate risks associated with product failures after launch. Rapid prototyping fosters a culture of innovation while enabling informed decision-making.

3. Improved Collaboration

Prototypes serve as tangible representations of ideas, making it easier for teams to communicate their visions to stakeholders. This improved collaboration can result in quicker approvals and better alignment across departments.

4. Competitive Advantage

Incorporating rapid prototyping into your product development not only speeds up delivery times but also positions your company ahead of competitors who may still rely on traditional prototyping methods. Being first to market with innovative products can significantly impact your bottom line.

DeepMould.net: Your Partner in Rapid Prototyping

As a leader in metal fabrication, DeepMould.net has extensive experience in providing rapid prototyping solutions tailored to meet your business's unique needs. Our commitment to quality, efficiency, and customer satisfaction sets us apart. Here's how we can help:

1. Tailored Solutions

We recognize that each project is different. Our team works closely with clients to understand their objectives and challenges, offering customized prototyping solutions that align with their specific requirements.

2. State-of-the-Art Equipment

DeepMould.net leverages cutting-edge technology, ensuring that your prototypes are produced with the highest level of precision and quality. Our facilities are equipped with the latest machinery, enabling us to handle a variety of materials and prototyping techniques.

3. Expert Guidance

With years of experience in the field, our professionals provide expert insights and guidance throughout the prototyping process. We assist in material selection, design optimization, and scaling production, ensuring a seamless workflow from concept to completion.

4. Reliable Turnaround Times

Your timelines are crucial. At DeepMould.net, we prioritize efficiency without compromising quality, delivering prototypes on time so you can stay ahead in your market.

Conclusion

Rapid prototyping in China offers businesses unparalleled advantages in speed, cost, and quality. By embracing this methodology, companies can innovate faster, reduce risks, and bring high-quality products to market efficiently. Partnering with DeepMould.net gives you access to advanced prototyping solutions supported by a dedicated team of experts ready to help you achieve your business goals.

To learn more about how we can assist you with your rapid prototyping needs, visit our website at DeepMould.net.

rapid prototype china